How Pumps Are Tested Before Shipping: Inside a Real Quality Check Process

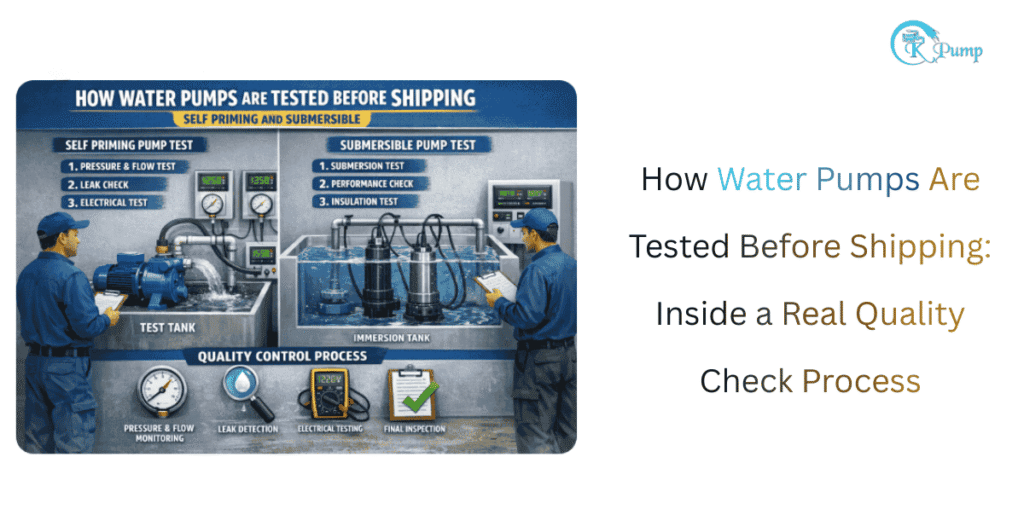

When a water pump leaves a factory, it shouldn’t just look good. It should work exactly as promised—under pressure, load, heat, and real-world conditions. That’s why serious manufacturers don’t rely on visual inspection alone. They test every pump before shipping.

In this guide, we’ll break down how pumps are tested before shipping, what parameters are checked, and why these tests matter for long-term performance. If you’ve ever faced early pump failure, low pressure, overheating, or noise issues, the root cause often traces back to poor or skipped testing.

This article explains the process in plain language—no marketing fluff, just how quality is verified.

Why Pre-Shipping Pump Testing Is Non-Negotiable

A water pump operates under continuous stress—electrical load, hydraulic pressure, and mechanical rotation. Even a small defect can grow into a major failure after installation.

Pre-shipping testing ensures:

The pump delivers the rated head and flow

Electrical components are safe and stable

The motor doesn’t overheat under load

No leakage, vibration, or imbalance exists

For a reliable water pump supplier, testing isn’t optional—it’s the last quality gate before the product reaches the user.

Stage 1: Visual & Dimensional Inspection

Before powering the pump, technicians inspect:

Casting quality (cracks, porosity, uneven surfaces)

Shaft alignment and bearing seating

Impeller clearance

Seal placement and housing fitment

This step may seem basic, but many common water pump problems—like vibration or leakage—start with mechanical misalignment.

Stage 2: Electrical Safety Tests (Motor Health Check)

The motor is the heart of the pump. Electrical testing verifies whether it’s safe, efficient, and built to last.

1. Insulation Resistance Test

Checks insulation quality between windings and the motor body. Poor insulation leads to:

Electric leakage

Short circuits

Early motor burnout

High insulation resistance indicates strong winding quality, which directly affects motor life.

2. High Voltage (Hi-Pot) Test

A higher-than-normal voltage is applied briefly to ensure insulation can withstand electrical stress without breakdown.

This step filters out hidden defects that may not appear during normal operation but fail later.

Stage 3: No-Load Run Test

The pump is run without hydraulic load to observe:

Smooth motor rotation

Abnormal noise

Vibration levels

Current consumption

If the motor draws excessive current even at no load, it signals internal friction, winding imbalance, or bearing issues.

Stage 4: Hydraulic Performance Testing

(Head, Flow Rate, and Power in Water Pumps)

This is the most critical test.

The pump is connected to a closed-loop test bench where engineers measure:

Head (pressure output)

Flow rate (water delivery volume)

Power consumption

These parameters are compared against design specifications.

Why This Matters

If head or flow is lower than promised:

Tanks take longer to fill

Irrigation systems underperform

Pressure fluctuates in domestic use

If power consumption is higher:

Electricity bills increase

Motor heating rises

Efficiency drops

Accurate testing of head, flow rate, and power in water pumps ensures the pump performs as expected in real installations—not just on paper.

Stage 5: Load Test (Real Operating Conditions)

The pump is run under full load for a fixed duration.

During this test, technicians monitor:

Motor temperature rise

Current stability

Noise and vibration

Seal leakage

This step identifies issues that appear only after continuous operation, such as:

Thermal imbalance

Seal failure

Skipping this test is one of the main reasons pumps fail within the first few months of use.

Stage 6: Leakage & Pressure Hold Test

Water pumps must be leak-proof under pressure.

The pump casing, seals, and joints are checked for:

Static leaks

Pressure drops

Seal deformation

A small leak during factory testing can turn into a major site failure later, especially in submersible or high-head applications.

Stage 7: Noise & Vibration Analysis

Excess vibration isn’t just annoying—it damages bearings, shafts, and windings over time.

Testing includes:

Bearing noise detection

Shaft balance verification

Vibration amplitude measurement

Many water pump maintenance complaints start with “the pump is making noise.” Proper vibration testing prevents this at the source.

Stage 8: Final Parameter Matching & Tagging

Before packing, the pump’s tested values are recorded:

Voltage

Current

Head

Flow

Power

Only pumps that fall within acceptable tolerance are approved for dispatch. Units that fail are reworked or rejected.

This traceability is a sign of a responsible manufacturer—not all suppliers follow it.

How Testing Helps You Choose the Right Water Pump

Understanding how pumps are tested helps buyers choose the right water pump for their application.

When evaluating a supplier, ask:

Is every pump tested or only samples?

Are performance parameters measured or assumed?

Is load testing part of the process?

A pump that’s properly tested:

Lasts longer

Uses less power

Requires less maintenance

Performs consistently across seasons

Poor Testing = Predictable Failures

Most common water pump problems are not design flaws—they’re quality control failures:

| Problem | Root Cause |

|---|---|

| Motor overheating | Poor winding or skipped load test |

| Low pressure | Inaccurate head-flow testing |

| Excess noise | No vibration analysis |

| Early burnout | Weak insulation, no hi-pot test |

| Leakage | Skipped pressure test |

Good testing doesn’t make pumps expensive.

Bad testing makes pumps costly after installation.

Final Thoughts: Testing Is the Real Brand Value

Paint, packaging, and price don’t define pump quality—testing does.

A manufacturer that invests in:

Electrical safety checks

Hydraulic performance validation

Load and endurance testing

is not just selling a product—they’re reducing failure risk for the end user.

Whether you’re a dealer, installer, or end customer, understanding how pumps are tested before shipping helps you make better decisions and avoid avoidable problems later.

In water pumps, reliability isn’t claimed.

It’s tested—before the pump ever leaves the factory.