Copper vs Aluminum Winding: Which Is Better for Water Pumps?

When people compare water pumps, they often look at flow rate, head, or price. But one of the most important decisions is hidden inside the motor: winding material.

For any manufacturer of water pump, the choice between copper winding and aluminum winding directly affects efficiency, lifespan, heat tolerance, and long-term maintenance.

So which one is actually better—and why?

Let’s break it down in a clear, no-marketing way.

What Is Motor Winding and Why It Matters

Motor winding is the coil of conductive wire inside a pump motor that carries electric current and creates a magnetic field. That magnetic field is what turns electrical energy into mechanical rotation.

If winding quality is poor, even the best pump design will fail early.

Good winding means:

Lower heat generation

Stable current flow

Better load handling

Longer motor life

This is why winding material is a core quality marker, not a minor detail.

Copper Winding: How It Works in Real Conditions

Copper has been the industry standard for decades, and for good reason.

Key Properties of Copper

High electrical conductivity

Low resistance

Excellent heat dissipation

Strong mechanical strength

In simple terms, copper allows electricity to flow more easily while producing less heat.

Real-World Impact in Water Pumps

Motor runs cooler even during long hours

Handles voltage fluctuation better

Less stress on insulation

Lower chances of coil burn

For applications like agriculture, industrial water supply, borewell pumps, and continuous operation systems, copper winding significantly reduces failure risk.

Most premium water pump manufacturers prefer copper winding for pumps designed to last 8–12 years with proper usage.

Aluminum Winding: Where It Fits (and Where It Doesn’t)

Aluminum winding is mainly used to reduce manufacturing cost.

Key Properties of Aluminum

Lower cost than copper

Lighter weight

Higher electrical resistance

Generates more heat under load

To compensate for higher resistance, aluminum winding requires thicker coils. Even then, heat buildup remains higher than copper.

Practical Effects

Motor heats up faster

Insulation degrades sooner

Higher risk of winding failure

Shorter service life

Aluminum winding can work in:

Low-duty domestic pumps

Intermittent usage

Stable voltage environments

But under heavy load or long run time, aluminum winding becomes a limiting factor.

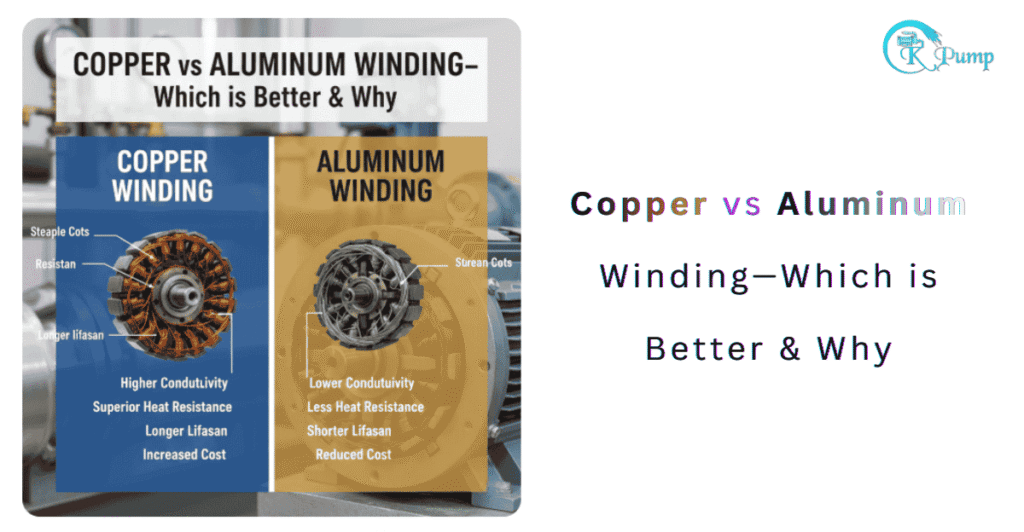

Copper vs Aluminum Winding: Side-by-Side Comparison

| Factor | Copper Winding | Aluminum Winding |

|---|---|---|

| Conductivity | Very High | Moderate |

| Heat Generation | Low | High |

| Energy Efficiency | Better | Lower |

| Motor Life | Longer | Shorter |

| Load Handling | Strong | Limited |

| Repair Frequency | Less | More |

| Initial Cost | Higher | Lower |

This comparison explains why copper winding pumps usually cost more upfront—but save money over time.

Energy Efficiency and Power Consumption

A pump with copper winding consumes less electricity for the same output.

Why?

Lower resistance = less energy lost as heat

Motor reaches optimal RPM faster

Reduced current draw

Over years of operation, this difference shows clearly on electricity bills—especially for farmers, industries, and commercial users.

From an efficiency standpoint, copper winding aligns better with modern energy-saving standards followed by reputed manufacturers.

Heat, Insulation, and Long-Term Reliability

Heat is the silent killer of pump motors.

Excess heat leads to:

Insulation breakdown

Short circuits

Reduced torque

Sudden motor failure

Copper winding dissipates heat faster, keeping internal temperature stable. Aluminum winding traps more heat, which slowly damages insulation—even if the pump seems to work fine initially.

This is why many early pump failures are wrongly blamed on “manufacturing defects” when the real cause is winding material + operating conditions.

Impact on Water Pump Maintenance

From a Water Pump Maintenance perspective, winding material makes a big difference.

Copper Winding Pumps

Longer intervals between servicing

Fewer rewinding cases

Stable performance over time

Aluminum Winding Pumps

More frequent heating complaints

Higher rewinding frequency

Reduced resale value

Maintenance cost over 5–7 years often exceeds the initial price difference between copper and aluminum pumps.

Common Installation Mistakes That Damage Winding

Even the best winding can fail if installation is poor. Some Common Installation Mistakes include:

Incorrect cable size causing voltage drop

Poor earthing

Running pump without water (dry run)

Wrong capacitor rating

Improper alignment in monoblock pumps

These mistakes affect aluminum winding faster, but copper winding is not immune either. Correct installation is critical regardless of winding type.

How Manufacturers Decide Which Winding to Use

A serious manufacturer of water pump doesn’t choose winding material randomly.

Copper winding is selected when:

Pump is designed for continuous duty

Brand focuses on long-term reliability

Market expects premium performance

Aluminum winding is usually chosen when:

Price sensitivity is the top priority

Pump is meant for short, occasional use

Understanding this helps buyers align expectations with actual usage.

Which Winding Should You Choose?

Choose Copper Winding if:

Pump runs daily or for long hours

Voltage fluctuation is common

You want lower maintenance and longer life

Choose Aluminum Winding if:

Usage is limited and intermittent

Budget is extremely tight

Load conditions are mild

For most agricultural, industrial, and commercial applications, copper winding is the safer and smarter choice.

Final Verdict: Copper vs Aluminum Winding—Which Is Better & Why

Copper winding is not just “better”—it is more reliable, more efficient, and more durable in real operating conditions.

Aluminum winding may reduce initial cost, but it increases long-term risk.

For users who value performance, longevity, and peace of mind, copper winding remains the clear winner.

And for responsible water pump manufacturers, winding choice is not a cost decision—it’s a quality commitment.