How Water Pumps Work: Simple Breakdown for First-Time Buyers

If you’re buying a water pump for the first time, the biggest challenge is usually not choosing the brand — it’s understanding how pumps actually work.

People often search for horsepower, head, and price, but without understanding the basics, every model looks similar and every salesperson sounds convincing.

Whether you visit a local shop or talk to a water pump manufacturer, you’ll realize that knowing the fundamentals helps you compare models confidently and choose the right pump for your needs.

The truth is simple:

Once you know how a water pump works, choosing the right pump becomes easier, cheaper, and problem-free.

This guide explains the fundamentals in plain language — no engineering confusion — so you can walk into a shop or browse online with more confidence.

What a Water Pump Really Does

At its core, a water pump does one job:

it moves water from one place to another using mechanical force.

That could mean:

pulling water from a borewell into storage

boosting pressure to reach upper floors

circulating water inside a building

transferring water for agriculture

But the way it does this is what matters. A water pump creates flow and pushes water using pressure, similar to how your heart pumps blood.

Without pressure, water would just stay still.

Without flow, pressure would be useless.

A pump balances both, based on the design and motor capacity.

The Basic Components That Make a Pump Work

Before understanding the process, get familiar with the main parts that make every pump run:

| Component | What It Does | Why It Matters |

|---|---|---|

| Motor | Powers the pump using electricity | Decides efficiency & durability |

| Impeller | Rotating fan that pushes water | Controls pressure & flow |

| Pump Casing | Holds and directs the water | Prevents leakage, maintains pressure |

| Suction Pipe | Brings water into pump | Affects priming & flow stability |

| Discharge Pipe | Sends water out | Impacts how far water travels |

| Mechanical Seal | Stops internal leakage | Protects winding & bearings |

| Winding | Motor coils that create rotation | Determines pump life & heating |

You don’t have to remember all of these — just know that quality of materials inside directly affects lifespan and repair cost.

How Water Pumps Actually Move Water (Simple Physics)

Imagine spinning a fan underwater — water gets pulled and thrown outward.

A pump does exactly that, but inside a closed chamber so pressure builds.

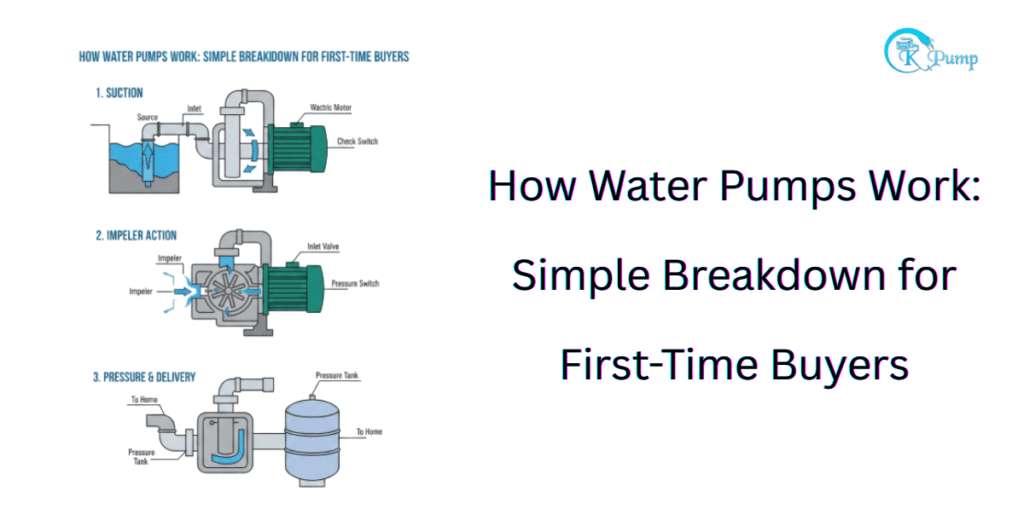

Here’s the step-by-step breakdown:

Motor turns ON

Impeller begins rotating rapidly

Rotation creates low pressure at the center

Water gets pulled in from the suction pipe

Impeller blades push water outward using centrifugal force

Water exits through discharge pipe with pressure

Continuous rotation keeps the flow steady

In short:

Motor creates rotation → rotation creates pressure → pressure creates flow.

When these three stay balanced, the pump performs consistently.

Why Pumps Need a Priming Process (in some models)

If you’ve ever heard the phrase “prime the pump first,” here’s what it means:

Some pumps, especially self-priming and centrifugal, need water filled inside before starting so the impeller can push water instead of air.

Without priming:

impeller spins freely

no suction happens

motor heats up and may burn

Submersible pumps don’t need priming because they are already underwater.

Quick tip:

If a pump suddenly stops giving pressure after maintenance or pipe change, loss of prime is often the reason.

The Three Pump Types First-Time Buyers Should Know

🔹 Submersible Pump

Placed underwater — ideal for borewells, underground tanks, agriculture.

no priming required

cools automatically due to water around it

strong suction for deep water levels

🔹 Self-Priming Pump

Stays outside water — great for homes and small buildings.

quick start after filling once

easy maintenance

perfect for boosting pressure

🔹 Centrifugal Pump

Common for industrial and agricultural usage.

powerful flow

suitable for transferring large water volumes

needs priming unless modified

Knowing the use case is more important than knowing the names.

Flow vs. Head: The Two Terms That Confuse Everyone

You’ll see these numbers in every pump brochure:

| Term | Meaning | Practical Explanation |

|---|---|---|

| Head (H) | How high water can be pushed | If your tank is on the 3rd floor |

| Flow (Q) | How much water comes out | How fast the tank fills |

Higher head = reaches taller buildings

Higher flow = fills faster

But there’s a balance:

When head increases, flow decreases — and vice-versa.

That’s why a pump with massive flow for ground houses may not work well for a 4-floor building.

Why Voltage Fluctuation Affects Pump Performance

In India, voltage rarely stays stable, especially in rural areas.

When voltage drops:

motor struggles

winding heats up

pressure reduces

A good water pump manufacturer designs pumps to handle these fluctuations with strong winding and insulation, reducing long-term failure.

Signs of a Good Pump for First-Time Buyers

If you’re buying your first pump, check these:

✔ Copper winding motor

✔ Warranty of at least 12 months

✔ Service availability nearby

✔ Strong pressure without overheating

✔ Balanced head and flow based on your usage

✔ Real pump weight (too light = less copper, weaker winding)

A pump that lasts 7–10 years costs less than replacing a cheap pump every 2 years.

When Should You Replace a Pump Instead of Repairing It?

Sometimes old pumps cost more in repairs than replacement.

Replace when:

rewinding happens more than twice a year

pressure drops even after servicing

pump vibrates or overheats consistently

electricity bill increases due to weak efficiency

Quick Checklist Before Buying

| Requirement | What to Choose |

|---|---|

| Borewell / Deep source | Submersible Pump |

| Home Pressure / Overhead Tank | Self-Priming Pump |

| Water Transfer / Farming | Centrifugal Pump |

| Long life & low maintenance | Copper winding + quality seal |

| Frequent power fluctuation | Voltage-resistant winding material |

Final Thought: Understanding Makes Buying Easier

Once you understand how water pumps work, you stop comparing only horsepower and price.

You begin seeing what really matters: winding quality, pressure balance, insulation, and durability.

A water pump is not just a machine — it’s a daily need.

Choosing the right one brings peace of mind for years.