Understanding Head, Flow Rate, and Power in Water Pumps (Explained Simply)

When people buy a water pump, most problems don’t come from poor quality—they come from wrong selection.

In almost every wrong selection case, three terms are misunderstood:

Head

Flow Rate

Power (HP / kW)

These are not technical buzzwords meant only for engineers. If you understand how these three work together, you can easily choose the right water pump for your application, whether it’s domestic, agricultural, or industrial.

This guide breaks everything down in simple language, with real-world logic—not textbook theory.

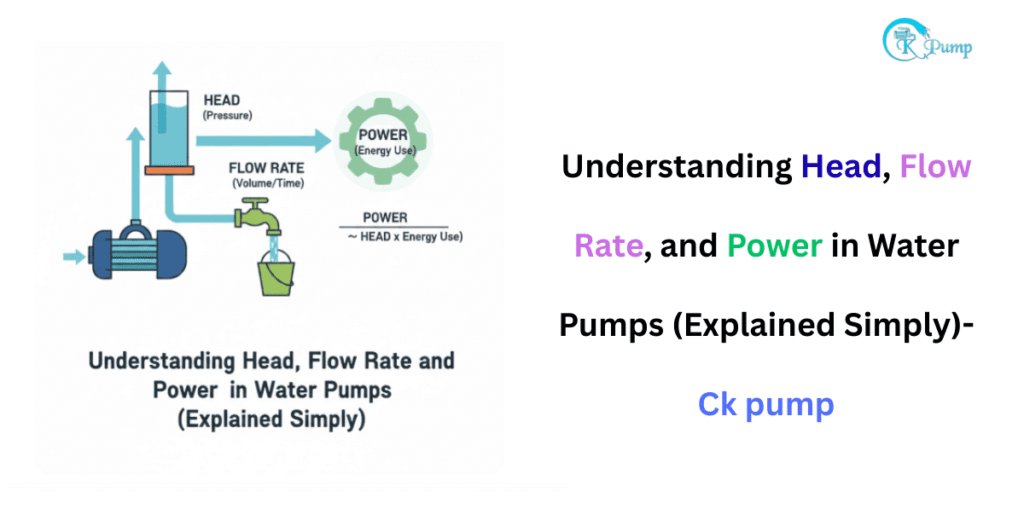

Why Head, Flow Rate, and Power Matter Together

Many users make this mistake:

“I need a 1 HP pump.”

But HP alone means nothing without head and flow rate.

A pump does not push water horizontally.

It lifts water against gravity and resistance, and that effort depends on:

How high the water needs to go (Head)

How much water you need (Flow Rate)

How much energy the pump must use to do both (Power)

Think of it like riding a bike:

Head = steepness of the road

Flow rate = speed

Power = your leg strength

You can’t judge performance by strength alone.

What Is Head in a Water Pump?

Head is the total vertical height the pump can lift water, measured in meters.

But here’s the important part:

Head is not just height.

It also includes pressure losses.

Types of Head You Should Know

Static Head

The actual vertical distance from water source to delivery point.Friction Head

Loss caused by:Pipe length

Pipe diameter

Bends, valves, elbows

Total Dynamic Head (TDH)

This is what really matters.

TDH = Static Head + Friction Losses

If your overhead tank is 15 meters high and your pipe losses add another 5 meters, your pump must handle at least 20 meters head.

Common Head Mistake

Many users select a pump rated at maximum head, not operating head.

If a pump’s max head is 30 meters, it does not mean it performs well at 30 meters.

Pumps work best in the middle of their head range, not at extremes.

What Is Flow Rate?

Flow rate tells you how much water the pump delivers over time.

It is measured in:

LPM (Liters per Minute)

LPH (Liters per Hour)

m³/hr (Cubic meters per hour)

Example:

60 LPM = 3,600 liters per hour

Why Flow Rate Drops as Head Increases

This is critical.

As head increases, flow rate decreases.

Every pump has a performance curve showing this relationship.

Low head → high flow

High head → low flow

There is no pump that gives maximum flow at maximum head.

If someone promises that, they’re selling you marketing—not engineering.

How to Decide the Right Flow Rate

Ask practical questions:

How many taps/showers/machines will run together?

How fast do you want the tank to fill?

Is it continuous operation or occasional use?

For example:

A home may need 30–60 LPM

Agriculture may need 200+ LPM

Industry depends on process load

Understanding Power (HP / kW)

Power is the energy required to deliver a specific flow rate at a specific head.

Measured as:

Horsepower (HP)

Kilowatt (kW)

Important Truth About Power

Higher HP does not automatically mean better performance.

Power increases when:

Head increases

Flow rate increases

Efficiency decreases

A poorly matched pump may consume more electricity while delivering less water.

Efficiency Matters More Than HP

Two pumps can both be 1 HP:

One delivers 50 LPM at 20 meters

Another delivers 80 LPM at the same head

Why?

Because of design and hydraulic efficiency.

This is why reputable manufacturers like CK Pump focus on optimized pump curves, not just HP ratings.

How Head, Flow Rate, and Power Work Together

These three are connected, not independent.

If you change one, the others change.

| Scenario | Result |

|---|---|

| Increase head | Flow rate drops, power demand rises |

| Increase flow rate | Requires more power |

| Poor pipe sizing | Increases head loss → higher power bills |

This is why pump selection must start with application data, not motor size

Reading a Pump Performance Curve (Simplified)

A pump curve shows:

X-axis → Flow rate

Y-axis → Head

The best operating zone is called the BEP (Best Efficiency Point).

Operating near BEP means:

Lower electricity consumption

Less vibration

Longer pump life

Running far from BEP causes:

Overheating

Seal failure

Motor damage

Real-Life Example

Application:

Overhead tank filling for a residential building

Vertical height: 12 meters

Pipe losses: 4 meters

Required flow: 40 LPM

Total Head Needed: 16 meters

Correct selection:

Pump whose curve delivers 40 LPM at ~16 meters

Power may be 0.5 HP or 1 HP, depending on efficiency

Wrong selection:

Choosing a 1 HP pump without checking curve

Leads to excess power consumption and poor output

Common Myths You Should Ignore

❌ “Higher HP means stronger pump”

❌ “Max head rating is what the pump will give daily”

❌ “One pump works for all applications”

❌ “Flow rate remains same at all heights”

Understanding the basics saves money, energy, and maintenance costs.

Why This Knowledge Matters Before Buying a Pump

If you match:

Correct head

Required flow rate

Efficient power rating

You get:

Lower electricity bills

Stable water pressure

Longer pump life

Fewer breakdowns

This is exactly why professional pump manufacturers design products around applications, not just motor sizes.

Final Takeaway

Before choosing any water pump, stop asking:

“How many HP is it?”

Start asking:

What is my total head?

What flow rate do I actually need?

At what point does the pump deliver both efficiently?

Once you understand how head, flow rate, and power work together, selecting the right pump becomes logical—not confusing.

If you want long-term performance, energy savings, and reliability, this understanding matters more than brand names or horsepower numbers.