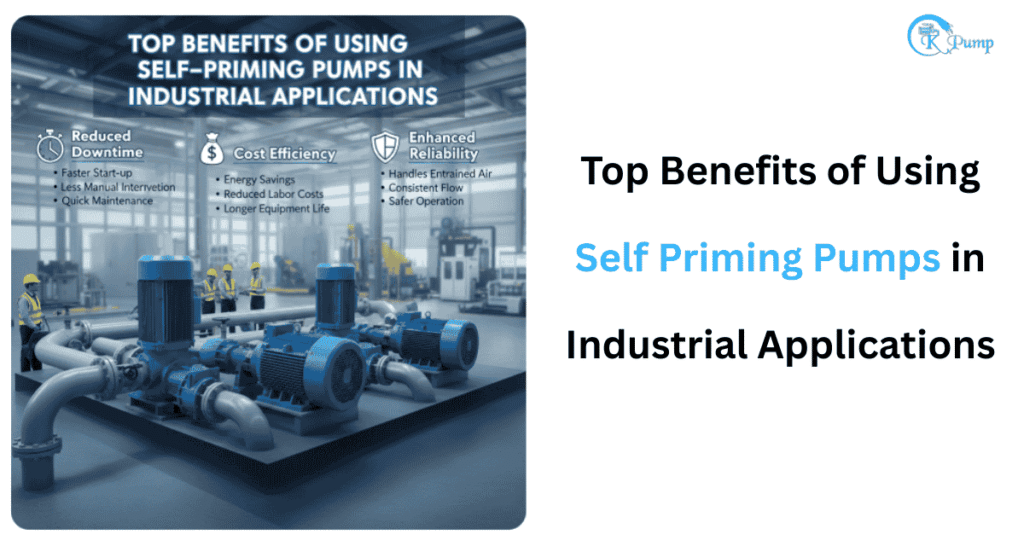

Top Benefits of Using Self Priming Pumps in Industrial Applications

Industrial operations depend heavily on uninterrupted fluid movement. Whether it’s water transfer, chemical handling, effluent management, or process circulation, pump reliability directly impacts productivity, safety, and operational costs.

Among the various pump types used across industries, self priming pumps stand out for their operational flexibility and reduced downtime—qualities that are consistently delivered by a reliable Ck water pump manufacturer with strong industrial expertise.

This article explains the core benefits of using self priming pumps in industrial applications, how they work, and why industries increasingly prefer them over conventional centrifugal pumps when sourcing solutions from an experienced Self priming water pump manufacturer.

What Is a Self Priming Pump?

A self priming pump is designed to evacuate air from the suction line automatically and create a vacuum that draws liquid into the pump casing without manual priming. Unlike standard centrifugal pumps, which require external priming before startup, self priming pumps retain enough liquid in the casing to re-prime themselves after shutdown.

This design makes them particularly useful in industrial environments where fluid levels fluctuate or suction conditions are inconsistent.

1. Reduced Downtime and Faster Restart

One of the most significant benefits of self priming pumps is their ability to restart automatically after power interruptions or maintenance shutdowns.

In industrial setups—such as manufacturing plants, processing units, and utilities—manual priming wastes time and often requires skilled intervention. Self priming pumps eliminate this dependency, allowing systems to resume operation quickly, which directly improves plant uptime and production continuity.

2. Ideal for Applications with Intermittent Flow

Many industrial processes do not maintain a continuous flow. Applications like:

Effluent transfer

Dewatering

Sump drainage

Batch processing

often experience air entering the suction line. Self priming pumps handle air–liquid mixtures more effectively than standard pumps, preventing air lock conditions that commonly disrupt centrifugal pump performance.

3. Flexible Installation Options

Self priming pumps can be installed above the fluid level, unlike conventional pumps that often require flooded suction.

This flexibility offers multiple advantages:

Easier access for inspection and servicing

Reduced risk of corrosion from submerged installation

Improved safety in hazardous or confined industrial environments

For industries dealing with chemicals, wastewater, or abrasive fluids, above-ground installation significantly simplifies maintenance planning.

4. Lower Maintenance Requirements

Because self priming pumps are designed to handle air without damage, they experience less mechanical stress during startup.

Key maintenance benefits include:

-

Reduced seal failures

-

Less cavitation-related damage

-

Longer bearing and impeller life

Over time, this results in lower maintenance costs and fewer unplanned breakdowns—an important consideration for cost-sensitive industrial operations.

5. Reliable Performance in Harsh Industrial Conditions

Industrial environments often involve:

Suspended solids

Slurries

Contaminated water

Temperature variations

Self priming pumps are commonly built with robust casings and non-clog impeller designs, making them suitable for handling challenging fluids without frequent performance degradation.

This reliability makes them a preferred choice in industries such as textiles, chemicals, construction, power plants, and municipal utilities.

6. Energy-Efficient Operation Over Time

While the initial power draw of a self priming pump may appear similar to standard pumps, their overall energy efficiency improves operationally due to:

Fewer restarts caused by air lock

Minimal idle running

Stable flow rates under varying suction conditions

Reduced downtime and consistent performance indirectly contribute to energy savings across the pumping system.

7. Improved Safety and Process Control

Manual priming often involves opening valves, handling fluids, or exposing workers to hazardous environments. Self priming pumps reduce human intervention, lowering safety risks.

From a process control perspective, automatic priming ensures consistent suction conditions, which helps maintain stable pressure and flow—critical for industrial automation systems.

When Should Industries Choose Self Priming Pumps?

Self priming pumps are particularly suitable when:

Fluid sources are below pump level

Suction lines may drain after shutdown

Air ingress is unavoidable

Continuous supervision is not practical

For industries seeking operational reliability, reduced manpower dependency, and long-term cost efficiency, self priming pumps offer a clear advantage.

Final Thoughts

The benefits of using self priming pumps in industrial applications go far beyond convenience. They directly address common industrial challenges—downtime, maintenance overhead, safety concerns, and inconsistent performance.

By eliminating manual priming and handling air more effectively, self priming pumps support smoother operations and predictable output. For industrial facilities focused on efficiency and reliability, investing in the right self priming pump solution is a strategic decision, not just a mechanical one.